TurkuSteve responds to growing demand for project shipments

The Port of Turku’s project shipment services have great significance to the industries in Southwest Finland, because they allow manufacturers to ship their products through their own “home port” Turku. That means short land transports, faster deliveries and reasonable transport costs.

TurkuSteve provides stevedoring and logistics services in the Port of Turku and has noticed the increase in project shipments and developed its own operations accordingly.

Major investments in development of own operations

”We have been developing our company’s equipment in the long term to suit both for performing normal stevedoring and logistics work as well as project loading. With the increasing demand for project shipments we have invested particularly in special equipment used in project loading. A good example is the X-lift special booms, we have two of those. X-lift is an excellent tool when the centring of the lifted unit must be automatic. Our X-lifts have lifting capacity of 20 and 50 tonnes, respectively, and the reach is at best 12 metres. The 12-metre reach makes the special boom also suited to lifting of long units, and a benefit of X-lift is the possibility to use it also as a normal boom”, says Kimmo Iljin, Managing Director of TurkuSteve.

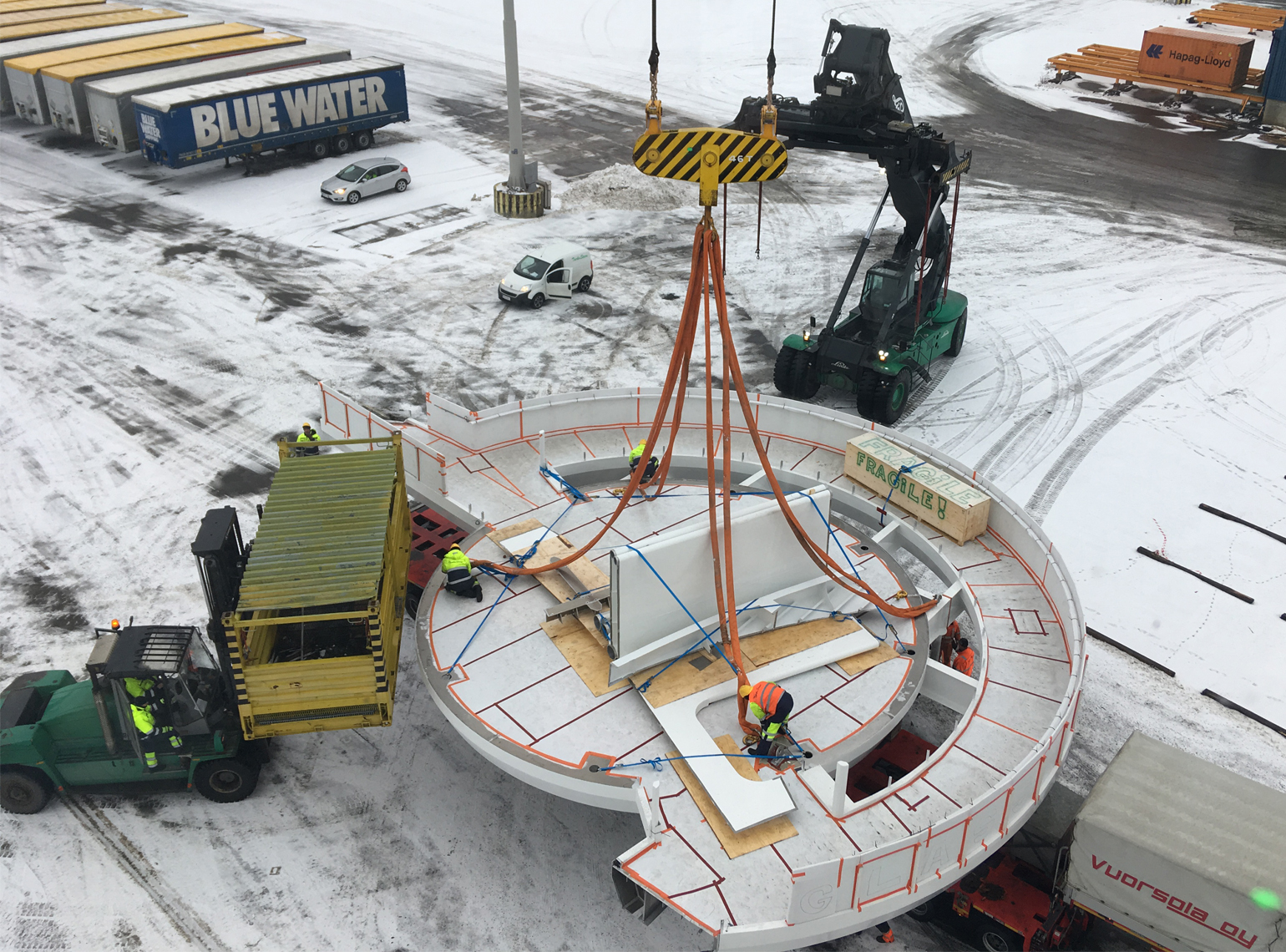

”In addition to the X-lifts, we have made major investments in exceptionally long and wide lifting slings which allow the lifting of products weighing up to 60 tonnes. We also have at our disposal dozens of different-sized forklifts with weighing capacity ranging from 1.5 to 45 tonnes. We have invested in the training of personnel using the apprenticeship model, which means that expertise has been passed from older stevedores to young ones while foremen have supported the training”, Kimmo Illjin says about TurkuSteve’s other investments in the development of project shipment services.

Demanding export shipments around the world

TurkuSteve’s development work together with professional and committed personnel has acquired many important project customers for the company. Items shipped around the world through the company include products of maritime industry equipment suppliers as well as steel and wood industry products. Alongside export shipments, the volume of imports has also increased.

”Our typical and at the same time most demanding project shipments are the special components to be installed in cruise liners being renovated in the Caribbean, such as surfing parks and water world equipment. Our new area of expertise is reception and loading of asphalt plants. The former are demanding, because the components going to cruise liners include a significant share of glass, and thus handling and protection of the cargo requires particular accuracy and care. And the latter are demanding due to the enormous size of asphalt plants, as one plant alone fills the cargo hold and deck of one vessel”, says Suvi Maksimainen, Logistics Secretary of TurkuSteve.

Successful loading calls for plenty of expertise

The handling of large and often very valuable project shipments requires particular care to ensure the safety of the cargo and the personnel. The loading is planned in co-operation with the officers of the vessel and the manufacturer of the products. TurkuSteve is responsible for the planning and implementation of the actual loading, from the reception of the goods to possible intermediate storage, and loading and fastening on the ship in such a way that endures even rougher conditions during the sea voyage.

”The work is first planned by TurkuSteve’s Production Director, Foremen and Logistics Secretaries. The actual loading is carried out by TurkuSteve’s stevedores and supervised by the Foremen. During the loading the stevedores are placed on the vessel and the quay or storage field. The work of the stevedores on board is guided by the signal man who gives directions to the shore on the loading order of different units. The stevedores on the shore transfer the products to the quay and fasten them for lifting. On the shore, one of the stevedores gives directions to the crane operator, and when the product is above the vessel, the signal man takes over”, Foreman Kari Nummelin describes the working process of project shipments.

Port of Turku’s location and resources are suited to project shipments

Kimmo Iljin, Managing Director of TurkuSteve, thinks that the Port of Turku has good potential to increase its share of the project shipments in Finland. The Port has good hinterland connections, although the condition of the road network should be improved further. In addition, the Port of Turku has large outdoor storage areas and plenty of room for intermediate storage of demanding project shipments, and TurkuSteve also offers large sheltered storage facilities. The most important wish for improvement concerns crane services. Mr Iljin hopes that the Port of Turku would invest in a harbour crane with lifting capacity of e.g. 100 tonnes.

Text: Kari Ahonen

Photos: Markku Koivumäki and Port of Turku