Engines supplied globally

The shipyard industry is now doing well in Finland, but the companies of the maritime cluster also export their products directly. Wärtsilä’s engines have been shipped around the world for decades. A quarter of the company’s net sales currently come from on-shore power plants.

The corridors of Wärtsilä’s Turku office are filled with international and youthful staff. The company operates in over 70 countries, and the Turku office provides, for example, training on operating and servicing of engines.

“Some 2,500 trainees from dozens of countries come to Wärtsilä’s Turku Training Center every year”, says Ari Schiestl, Category Manager, Logistics at Wärtsilä.

An excellent product is not enough

Reliability of delivery is the pride of Wärtsilä, and functioning logistics is one key element of that.

“The product has to be delivered to the right place at the right time. Failure to do so means that there is no successful product”, Mr Schiestl sums up.

Wärtsilä’s products are often exported by sea, even if the product were not destined for a ship. In Finland, the logistics related to transports is concentrated to the ports on the west coast. From the Port of Turku Wärtsilä’s finished products are shipped e.g. via Bremerhaven around the world.

“There are good further connections to, for example, China and Singapore which are important to us”, Mr Schiestl says.

Approximately 2.5 million kilos of consolidated shipments of Wärtsilä’s suppliers are annually transported from Turku via Travemünde to the corporation’s plant in Trieste. The goods from the suppliers are compiled together in the Port of Turku area and are then sent out as full trailers.

“Weekly shipments provide a suitable flow for the goods, as the Trieste plant also operates on weekly rotation”, Mr Schiestl says.

Goods going to Wärtsilä’s plant in Vaasa also arrive through the Port of Turku.

“Hundreds of different components are needed in the manufacture of engines, and the suppliers are located in different parts of the world.”

From engines to services

Let’s get back from sea to land. Many people associate Wärtsilä with the maritime cluster in particular. The operations of the Marine Solutions segment, however, only account for a little over one-third of the corporation’s total net sales today. The Energy Solutions segment has been growing for a long time.

The strength of Wärtsilä’s Energy Solutions expertise is the building of power plants that use many different fuels. It has achieved significant growth especially on the markets of gas power plants by winning market shares from turbine-driven power plants.

“You could say that we’re number one in the world in that”, Mr Schiestl says.

He has worked at Wärtsilä for 23 years and says that it’s not a question of supplying equipment, but serving the customers throughout the lifecycle of the project sold to them. Spare part, operating and administration services already account for over 45 per cent of the net sales of Wärtsilä Corporation.

“We don’t actually sell engines, but energy and everything related thereto. Instead of engines we should talk about energy know-how in which the customer purchases the supplied system as a lifecycle solution.”

The long last mile

For a corporation that operates in over 70 countries and often supplies its products to remote regions with difficult access logistics is a challenge. Wärtsilä has high requirements for its logistics partners.

“The most important thing is reliability, which means that the products shall be delivered undamaged to the right place at the right time. The price/quality ratio also has to be right”, says Kaj Seppälä, Manager, Transport & Logistics at Wärtsilä Marine Solutions.

Wärtsilä’s clientele is global and the operating environment is the whole world, but the logistics partner is required to have local knowledge.

According to Mr Seppälä, the shipments of the marine segment are always carried from port to port, but the logistics expertise is emphasised in the energy segment where turnkey projects are provided.

“There the so-called last mile can be in practice a thousand kilometres in a region with no proper roads. We may even have to build bridges and so on”, Mr Seppälä says.

According to him, logistics expertise is an important part of Wärtsilä’s reputation as a reliable supplier.

Failing in that may be fatal.

“It requires understanding of project logistics at practical level, advance studying of existing routes, and resources. If the product is of top quality, the logistics expertise also has to be. Succeeding on that last mile is the key to success in the whole project.”

Text Kalle Kirstilä

Photos Robert Seger

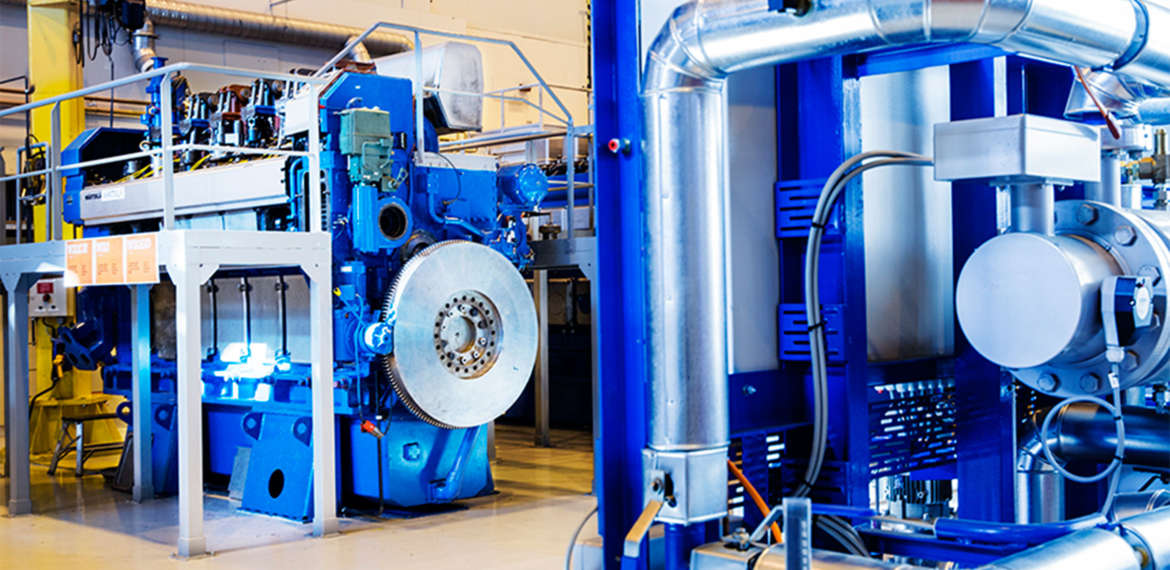

The most powerful diesel engine in the world

A product of the newest generation of Wärtsilä’s engines is Wärtsilä 31 manufactured at the Vaasa plant. It is the world’s most efficient 4-stroke diesel engine and weighs over 180 tonnes. Only six such engines have been sold so far, for example to Siberia, Norway and Denmark. The launch was preceded by long-time development work, and more experience is now being collected on the new low emission engine.

“We are only just starting with it, but the expectations are high”, says Ari Schiestl, Category Manager, Logistics.